MIX: All-round Goods-to-Person Picking Solution

⚡Quick Facts

Technology Performance Metrics

⭐Key Features

✨Benefits

🎯Applications

📝Detailed Information

Technology Overview

The Mushiny MIX system represents a new generation of goods-to-person picking solutions designed to enhance warehouse efficiency. It combines movable storage, autonomous mobile robots, and artificial intelligence to automate the transport and presentation of goods to picking personnel. This approach minimizes worker travel time and focuses human effort on the value-added task of selection. The system is engineered to handle a wide range of boxed items, offering a versatile solution for modern fulfillment centers looking to streamline their order picking processes.

How It Works

Core Principles

The core principle is a "goods-to-person" methodology. Instead of pickers walking to storage locations, the storage units (movable shelves containing boxes) are autonomously transported to stationary picking workstations. This is facilitated by robotics and AI, creating a highly efficient pick station environment.

Key Features & Capabilities

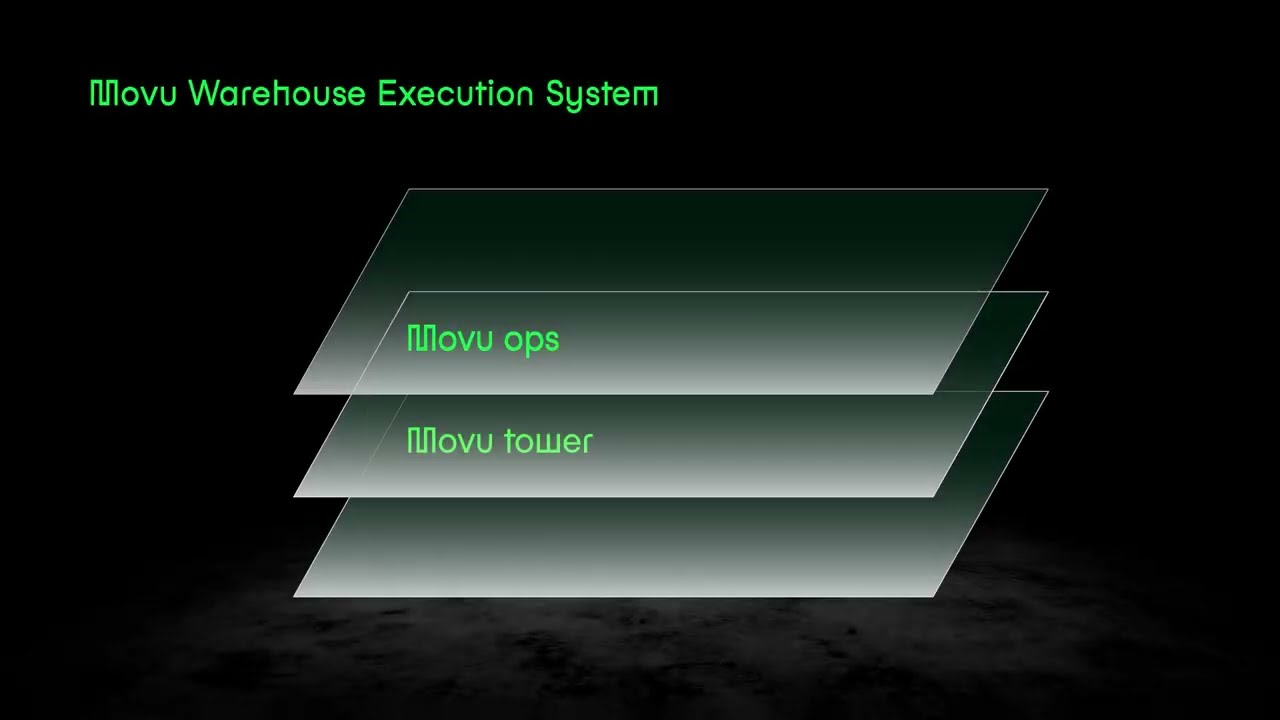

The T-series latent lifting robot is engineered for heavy-duty lifting and transport of loaded shelves, ensuring stable and reliable movement of inventory pods. The AI recognition and grabbing system eliminates manual search and handling, increasing pick speed and accuracy by autonomously identifying and retrieving the correct box. System integration flexibility is a major capability, as the solution can work in conjunction with the Muxing iRES system to incorporate standard latent pallets and shelves, allowing for a hybrid automation approach tailored to different product types within the same warehouse.

Advantages & Benefits

The primary benefit is a significant increase in picking efficiency and productivity. By bringing goods to the picker, travel time is eliminated, allowing for more picks per hour. The reduction in manual labor and error is achieved through AI-driven box handling, which decreases physical strain and improves order accuracy. Furthermore, the system offers scalable and adaptable storage, as the movable shelf design and compatibility with existing infrastructure allow operations to adjust storage density and workflow without a complete system overhaul.

Implementation Considerations

Implementing this system requires a significant initial investment in robotics, infrastructure, and software. Facilities must assess their floor flatness and layout to ensure smooth robot navigation. Integration with existing Warehouse Management Systems (WMS) via the iRES layer is crucial for seamless operation. Staff training is needed for personnel to operate and supervise the automated system effectively.

Use Cases & Applications

Ideal For

This solution is ideal for medium to high-volume fulfillment operations with a large variety of SKUs stored in boxes or totes, where order picking is a major bottleneck.

Conclusion

The Mushiny MIX system offers a compelling, highly automated goods-to-person solution that addresses core challenges in modern warehouse picking. By leveraging mobile robots and AI, it promises substantial gains in productivity and accuracy. Companies considering this technology should carefully evaluate their process flows, SKU characteristics, and integration requirements to ensure a successful deployment that meets their specific operational goals.