Smart Sequencing for Mixed Palletizing: Vertical Buffer Solutions

⚡Quick Facts

Technology Performance Metrics

⭐Key Features

✨Benefits

🎯Applications

📝Detailed Information

Technology Overview

Smart Sequencing for Mixed Palletizing addresses a fundamental bottleneck in automating the construction of complex, mixed-SKU pallets. While robotic palletizers can place cases, their efficiency is crippled if cases arrive in a random order. True automation requires products to be delivered to the robot in a precise sequence that respects business rules like stacking heavy items at the bottom, grouping product families together, and aligning with the store's shelf layout for efficient unloading ("shop floor loading"). This technology concept explores innovative, cost-effective methods to achieve this sequencing, often by adapting existing warehouse automation hardware—such as Vertical Lift Modules (VLMs)—to function as intelligent case buffers and sequencers upstream of the palletizing robot.

How It Works

Core Principles

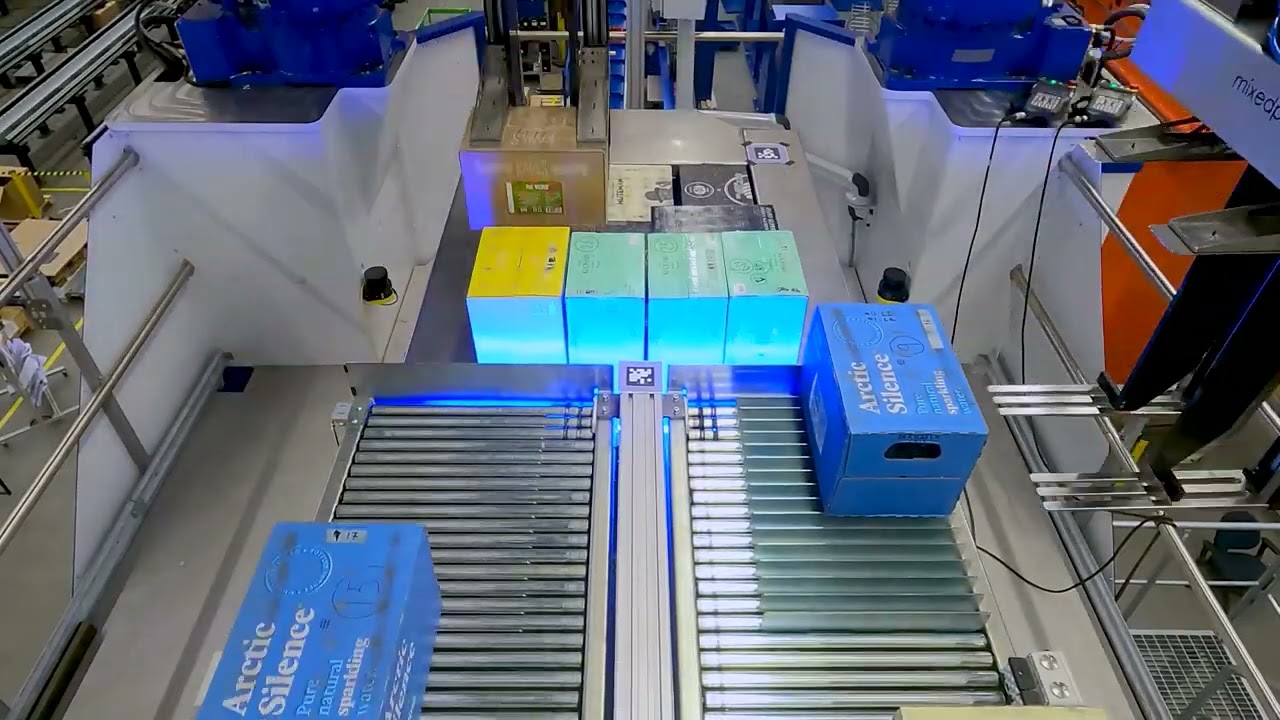

The core principle is to decouple the storage/retrieval of individual cases from the palletizing process and insert an intelligent buffering stage. Cases are temporarily stored after picking and before palletizing. A control system (WES/WCS) manages this buffer, releasing cases one by one in the exact order required for the specific mixed pallet being built, based on predefined stacking and grouping rules.

Key Features & Capabilities

Rule-Based Sequencing Intelligence: The system's "smart" capability lies in its software, which can process complex rules like heavy-to-light stacking, family grouping, and shop floor loading sequence to determine the exact case release order.

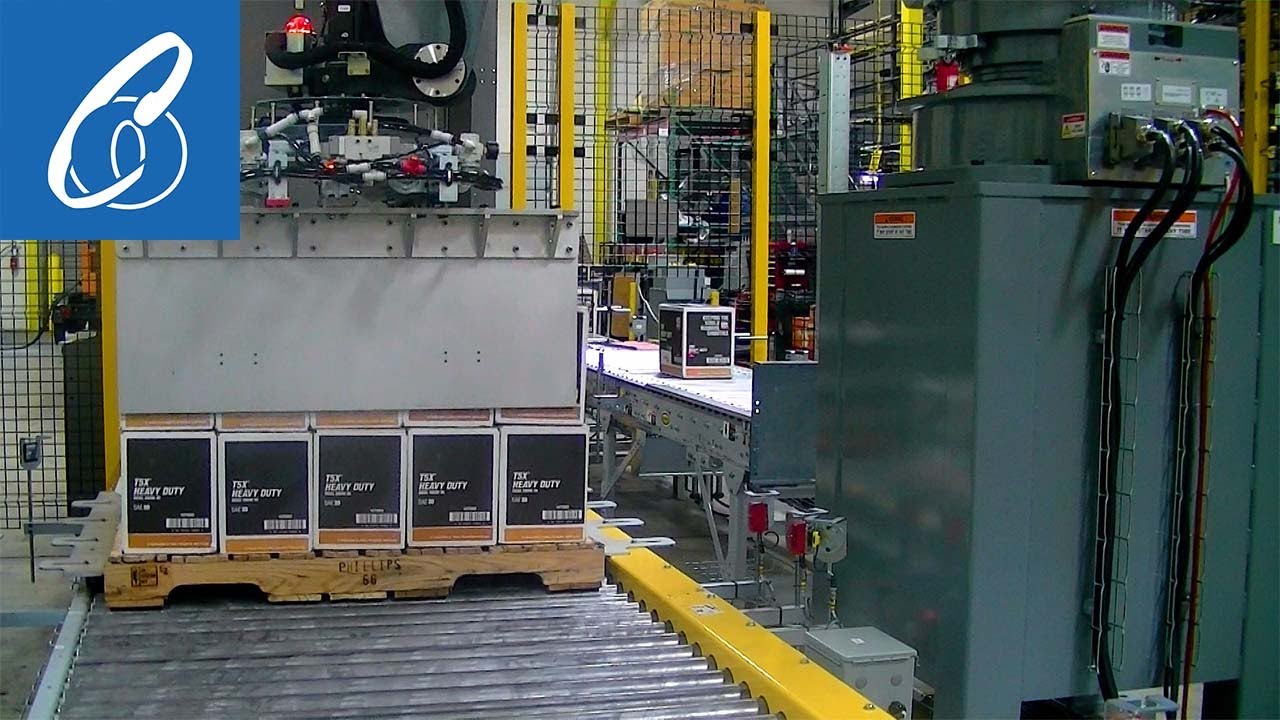

Repurposed Vertical Storage as Buffer: A key innovation is the proposed use of Vertical Lift Modules (VLMs), traditionally used for tools or small parts picking, as a high-density, automated case buffer. Their vertical footprint and automated tray delivery make them a compact candidate for sequencing.

Decoupling of Processes: By inserting a buffering and sequencing stage, it separates the variable-time picking process from the time-critical palletizing process, allowing both to operate at their own optimal pace and ensuring the robot is always fed correctly.

Advantages & Benefits

The primary benefit is enabling true, rules-based mixed pallet automation at a potentially lower cost by utilizing repurposed, existing storage technology. It provides a solution to the sequencing challenge, which is a major hurdle for many operations looking to automate mixed-case fulfillment. The use of a vertical buffer like a VLM offers a compact footprint, which is valuable in space-constrained facilities. This approach can increase overall system throughput and reliability by ensuring the robotic palletizer is never waiting for or receiving the wrong case.

Implementation Considerations

This approach requires a significant software layer to manage the complex sequencing logic and integrate the buffer system with both upstream picking and downstream palletizing. The feasibility of using a specific storage technology (like a VLM) as a case buffer depends on case dimensions, weight, and required throughput rates, necessitating detailed studies. The total solution is an integrated system, not just a standalone component, requiring careful design.

Use Cases & Applications

Ideal For

This concept is ideal for retail and grocery distribution centers that are automating or upgrading their mixed-case palletizing operations and are struggling with how to efficiently sequence a wide variety of case sizes and weights according to strict store delivery requirements.

Conclusion

Smart Sequencing for Mixed Palletizing represents a critical piece of the automation puzzle for building mixed pallets. By focusing on the often-overlooked sequencing challenge and proposing innovative, potentially cost-effective solutions like repurposing vertical storage systems, this approach makes advanced automation more accessible. Success depends on robust software logic and seamless integration of the buffer with surrounding material handling equipment. For operations committed to automating their mixed-case fulfillment in a way that truly respects store-friendly delivery requirements, investing in a smart sequencing solution is not just an option but a necessity to unlock the full potential of robotic palletizing.

📦Related Projects

Balluff Inc. Sensor Solutions Automated Warehouse

Balluff Inc. achieved a 177% throughput increase with an AutoStore system implemented by Kardex, featuring an innovative cross-building design installed in just 6 months.

Cutter & Buck Seattle Apparel Fulfillment Center

Cutter & Buck deployed an AutoStore system with 34,000 bins and 54 robots, implemented by Kardex, to streamline apparel fulfillment, reduce storage footprint by 50%, and achieve order turnaround in under 10 minutes.

ATS Group - Merelbeke Belgium Electrical Components Automated Warehouse

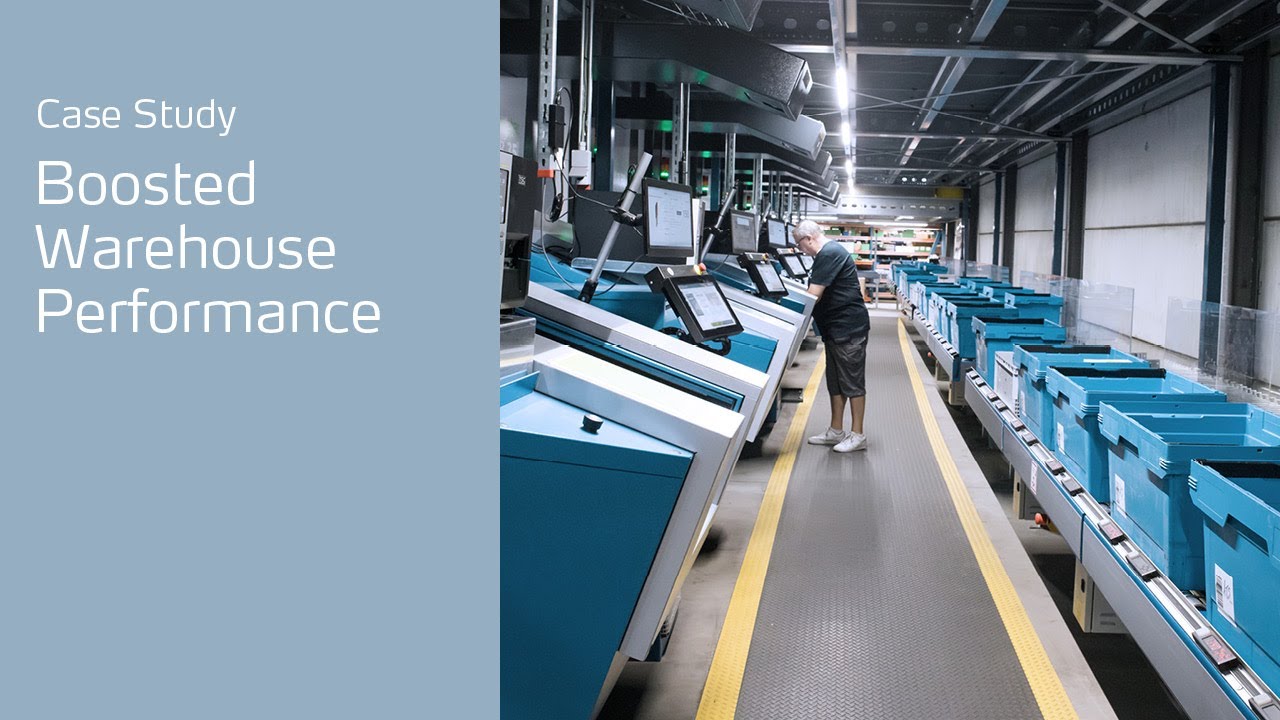

ATS Group implemented Kardex's 8 Vertical Buffer Module system with automated inbound and conveyor integration, saving over 50% floor space while increasing throughput from 500 to 900 orders.