Vertical Lift Module (VLM): Space Optimization and Ergonomic Retrieval

⚡Quick Facts

Technology Performance Metrics

⭐Key Features

✨Benefits

🎯Applications

📝Detailed Information

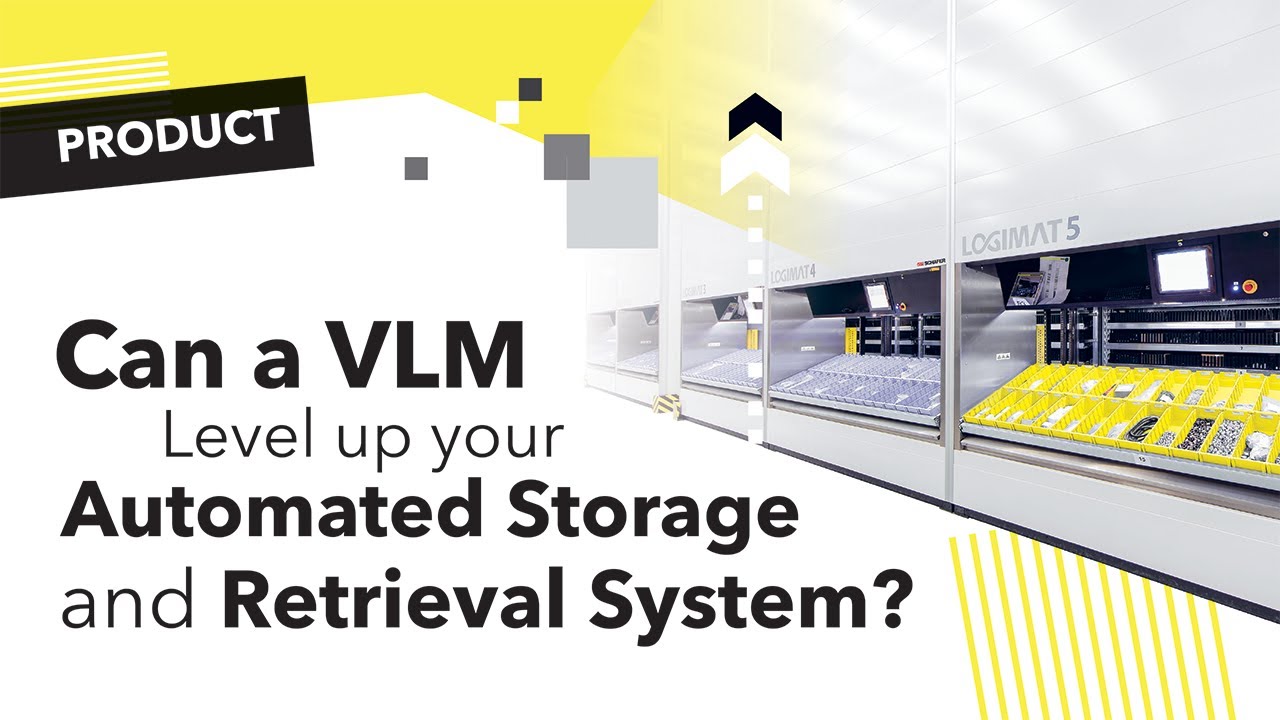

Technology Overview

The Kardex Shuttle is a fully automated Vertical Lift Module (VLM) system designed to address modern warehouse challenges of space constraints, operational efficiency, and worker safety. By utilizing vertical space, it transforms storage areas into high-density, organized systems. Its core principle involves an automated extractor that travels vertically and horizontally within a tall structure to store and retrieve trays containing items, delivering them to an ergonomic pick window. This technology is widely applied across manufacturing, distribution, and retail sectors for managing a vast array of small parts, components, and inventory items.

How It Works

Core Principles

The system operates on the principle of "goods-to-person" automation. Inventory is stored in trays stacked vertically within a closed cabinet. A centrally located, computer-controlled extractor shuttle automatically retrieves the required tray and brings it directly to the operator at an ergonomic workstation, eliminating manual searching and walking.

Key Features & Capabilities

The High-Density Vertical Storage capability allows the system to make full use of a facility's clear height, storing a large number of items in a footprint significantly smaller than traditional shelving. The Ergonomic Workstation is a critical feature, positioning the delivered tray at an optimal height to prevent bending, stretching, or lifting, thereby reducing fatigue and the risk of injury. Secure Inventory Management is achieved through controlled access, with items stored safely inside the enclosed system, reducing loss, damage, and improving inventory accuracy via software tracking.

Advantages & Benefits

The primary benefit is a dramatic increase in storage density, often freeing up to 90% of floor space compared to static shelving. This leads to better space utilization or the ability to consolidate operations. By bringing items to the operator, the system improves ergonomics, leading to higher productivity, fewer errors, and improved worker satisfaction. Furthermore, it enhances inventory control and security, as all transactions are logged, and physical access is restricted.

Implementation Considerations

Implementing a VLM like the Kardex Shuttle requires sufficient ceiling height to accommodate the system's vertical structure. The initial capital investment is higher than for passive storage solutions, necessitating a cost-benefit analysis focused on space savings and labor efficiencies. The system is ideal for handling a high volume of small to medium-sized items but is not designed for large palletized goods.

Use Cases & Applications

Ideal For

This technology is ideal for operations with high-value or high-mix inventory that need to maximize storage in a limited space while ensuring fast, accurate, and ergonomic order fulfillment.

Conclusion

The Kardex Shuttle Vertical Lift Module presents a compelling automation solution for businesses looking to optimize their storage footprint and improve operational ergonomics. By automating storage and retrieval, it delivers tangible benefits in space savings, productivity, accuracy, and workplace safety. For facilities handling a high volume of small items within manufacturing, distribution, or retail, implementing a VLM can be a strategic step towards a more efficient and organized logistics operation.

📦Related Projects

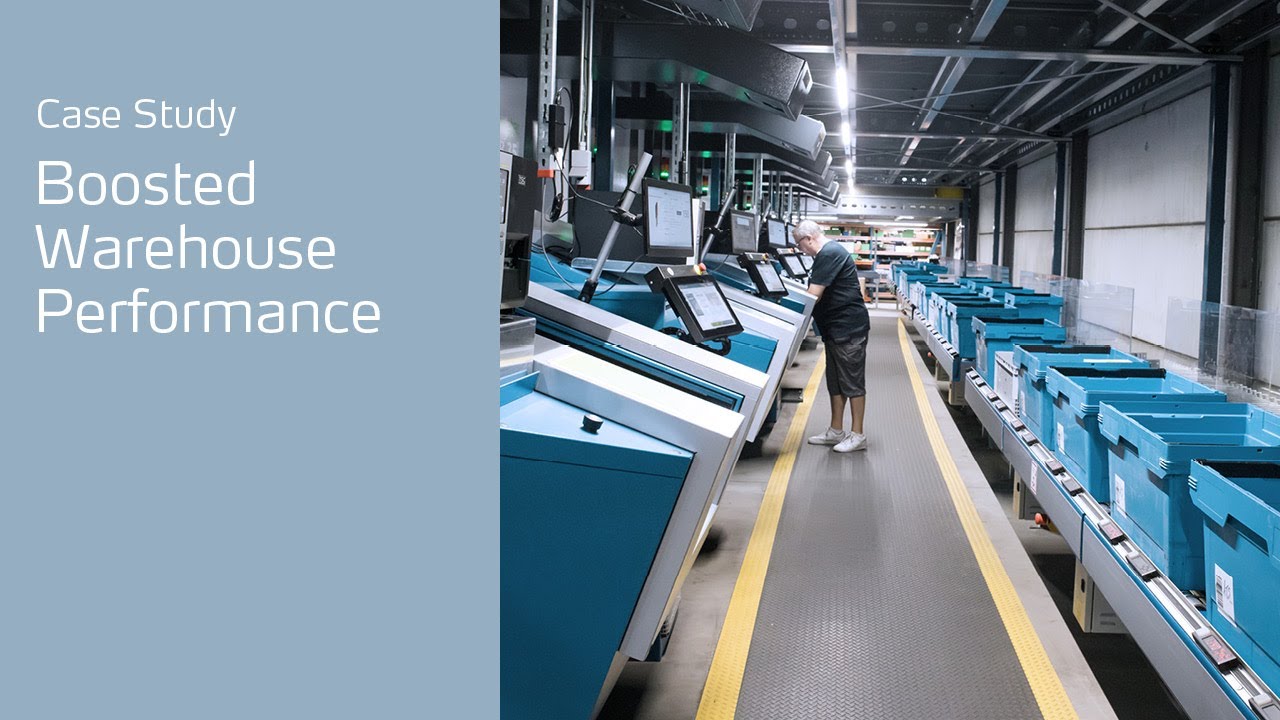

Balluff Inc. Sensor Solutions Automated Warehouse

Balluff Inc. achieved a 177% throughput increase with an AutoStore system implemented by Kardex, featuring an innovative cross-building design installed in just 6 months.

Cutter & Buck Seattle Apparel Fulfillment Center

Cutter & Buck deployed an AutoStore system with 34,000 bins and 54 robots, implemented by Kardex, to streamline apparel fulfillment, reduce storage footprint by 50%, and achieve order turnaround in under 10 minutes.

ATS Group - Merelbeke Belgium Electrical Components Automated Warehouse

ATS Group implemented Kardex's 8 Vertical Buffer Module system with automated inbound and conveyor integration, saving over 50% floor space while increasing throughput from 500 to 900 orders.