Evo Shuttle: High-Performance Automated Shuttle System

⚡Quick Facts

Technology Performance Metrics

⭐Key Features

✨Benefits

🎯Applications

📝Detailed Information

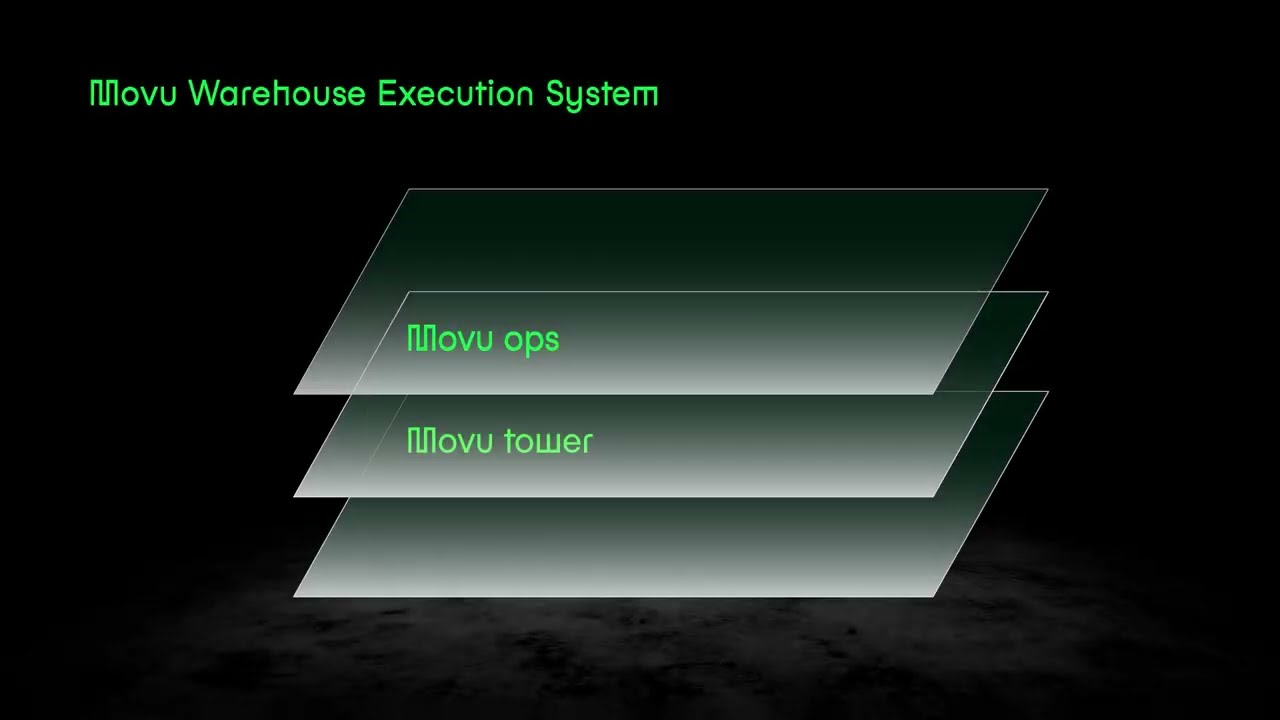

Technology Overview

The Evo Shuttle by KNAPP is an automated storage and retrieval system positioned as the fundamental, high-performance engine for modern order fulfillment operations. It is more than just a storage technology; it is designed to be the central, intelligent core that drives efficiency and speed across the warehouse. By utilizing a fleet of automated shuttles operating within a dense storage matrix, the system handles the rapid movement of totes or trays containing goods. Its primary design goal is to maximize both flexibility and order processing efficiency, making it a critical component for businesses facing the intense demands of e-commerce, micro-fulfillment, and omnichannel retail. The system emphasizes adaptability, allowing it to be tailored to specific operational needs, and scalability, ensuring it can grow alongside a business. Furthermore, it is presented as an integrated solution from a single source, aimed at interconnecting all warehouse processes into a seamless, monitored flow to achieve sustainable, high-quality fulfillment.

How It Works

Core Principles

The system operates on the principle of a high-density, grid-based shuttle matrix. A coordinated fleet of autonomous shuttle vehicles operates on multiple levels within a rack structure. These shuttles are directed by a central Warehouse Execution System (WES) to store incoming containers and retrieve requested items at high speed, forming the dynamic "core" of material flow.

Key Features & Capabilities

High-Performance Core Architecture is its defining feature. The system is engineered not just for storage but as the primary throughput engine, capable of meeting the extreme speed and volume requirements of direct-to-consumer and omnichannel fulfillment.

Maximum Flexibility and Efficiency are engineered outcomes. The software and shuttle fleet are designed to adapt to changing order profiles, peak demands, and varying SKU velocities, ensuring that order processing efficiency is constantly optimized.

Inherent Scalability and Adaptability allow the system to evolve. Businesses can start with a configuration that matches current needs and scale the shuttle fleet, storage levels, and workstations incrementally. The system can also be adapted to different product types and workflows.

Advantages & Benefits

The primary advantage is unmatched throughput and responsiveness for order fulfillment. By centralizing and accelerating the storage/retrieval process, the system dramatically reduces order cycle times, enabling same-day or next-hour delivery capabilities.

It simplifies complex logistics operations through integrated automation. By acting as the interconnected core, it brings cohesion to receiving, storage, picking, and sorting, reducing manual handling, errors, and operational complexity.

The system provides a scalable path to sustainable growth. Its modular and scalable nature protects the automation investment, allowing capacity and performance to be added precisely when needed, supporting business growth without disruptive overhauls.

Implementation Considerations

As a high-performance core system, it represents a substantial strategic investment. The total cost includes the shuttle matrix, software, and integration, requiring a clear business case focused on competitive advantage through speed and flexibility.

Full value realization depends on holistic process integration. To form the "constant flow," the Evo Shuttle must be seamlessly integrated with upstream (receiving/decanting) and downstream (picking/packing/shipping) processes, which requires comprehensive project planning.

Ongoing system monitoring and software optimization are crucial. The promise of monitoring every step and maximizing efficiency relies on leveraging the system's software intelligence, necessitating skilled oversight and continuous tuning.

Use Cases & Applications

Ideal For

This system is ideal for retailers and brands with a strong e-commerce presence, operators of micro-fulfillment centers in urban areas, and large omnichannel distributors who need to fulfill orders from a vast assortment of SKUs with extreme speed and accuracy.

Performance Metrics

The content emphasizes qualitative high-performance metrics: increased order processing efficiency to the maximum, flexibility maximized, and the ability to accelerate every step of fulfillment. It is positioned to deliver the performance needed to "thrill customers and stay on top," indicating metrics focused on order cycle time, system uptime, and scalability.

Conclusion

The KNAPP Evo Shuttle system is a premium, integrated automation solution for businesses where fulfillment speed and flexibility are critical competitive differentiators. It goes beyond simple storage automation to offer a programmable, scalable core that can adapt to the volatile demands of modern commerce. For companies aspiring to lead in e-commerce, execute flawless omnichannel strategies, or deploy efficient micro-fulfillment networks, the Evo Shuttle provides a powerful technological foundation. Implementing such a core system is a major undertaking that requires partnership with the vendor for design, integration, and optimization. However, for operations targeting best-in-class fulfillment performance, the investment can deliver transformative gains in speed, accuracy, and operational agility, forming the strong core needed to master complex supply chain challenges.

📦Related Projects

Peak Pharmacy Bolsover Distribution Center

Peak Pharmacy implemented KNAPP automation to merge three warehouses into one, automating prescription dispensing and enabling next-day delivery to 134 pharmacies across England.

Selfar SA Thessaloniki Pharmaceutical Distribution Center

Selfar SA implemented KNAPP's OSR Shuttle Evo solution for pharmaceutical wholesale distribution, achieving world-record ramp-up in one week despite COVID-19 challenges.

DSV Venlo Distribution Center

DSV commissioned KNAPP with an omnichannel fulfilment solution for their 60,000 sqm distribution centre in Venlo, handling textile and sports sectors for European supply chain centralization.