Double Deck Trailer Chain Track System

⚡Quick Facts

Technology Performance Metrics

⭐Key Features

✨Benefits

🎯Applications

📝Detailed Information

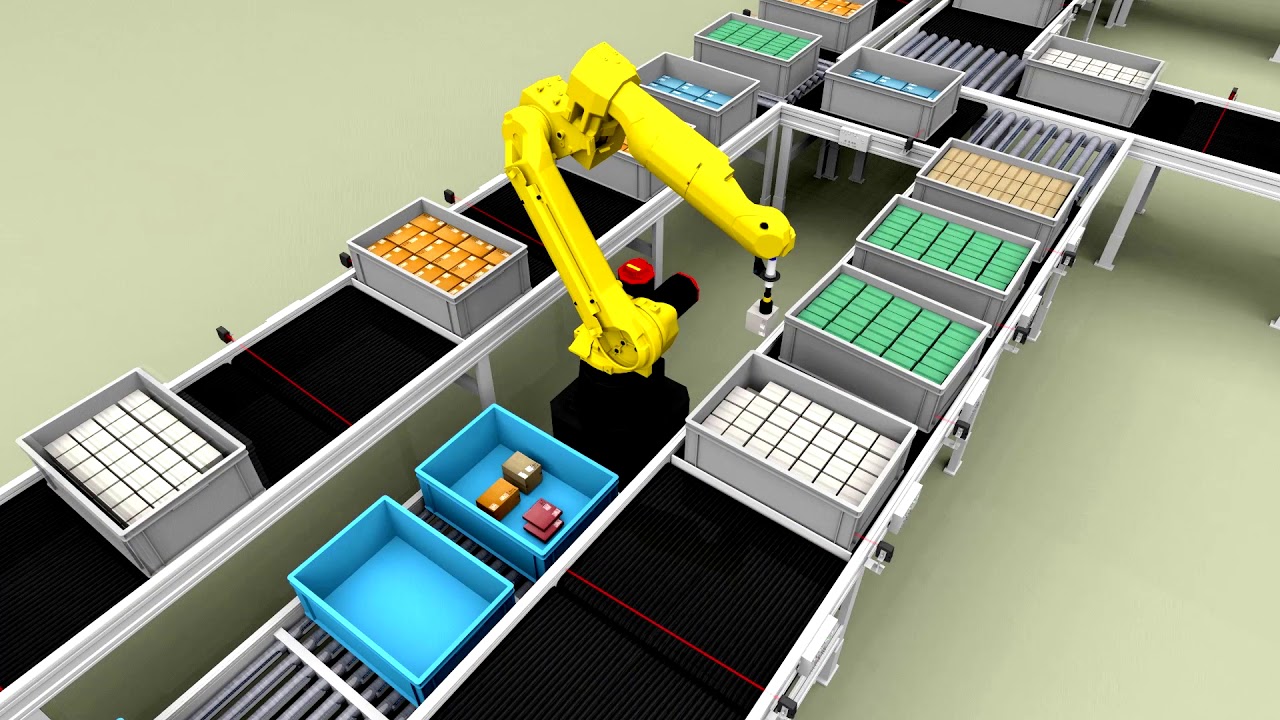

Technology Overview

The Double Deck Trailer Chain Track System by AncraSystems is a specialized material handling solution designed for the automated loading of mixed-height, palletized goods directly into transport trailers. This technology transforms a standard trailer into an automated receiving vessel by integrating a permanent chain track conveyor system on two levels: the trailer floor and an elevated steel support deck. This system works in concert with an external automated loading machine (such as the Skateloader) to enable rapid, "one-shot" loading of entire mixed pallet loads. A key component is a unique, in-house designed load securing mechanism that locks the cargo in place once loaded, addressing the critical challenge of securing goods, especially flat panels like flooring materials, during transit over sloped roads.

How It Works

Core Principles

The system operates on the principle of a permanently installed, multi-level conveyor inside the trailer. When aligned with an external automated loader, the internal chain tracks activate to receive and position pallets. After loading, integrated securing devices engage to prevent longitudinal and lateral movement of the palletized load during transport.

Key Features & Capabilities

Integrated Double-Deck Conveyor: The system features chain tracks on two levels within the trailer. This design allows for the efficient stacking and transportation of pallets with non-uniform heights, maximizing the use of the trailer's cubic volume.

High-Speed, One-Shot Loading: Engineered to work with automated loaders, the system enables the complete loading of a 13.5-meter trailer in approximately 3 minutes. This "one-shot" process eliminates multiple loading cycles and manual adjustment.

Unique Integrated Load Securing: A standout feature is the built-in load securing system. It is designed to prevent pallet shift during transit, a critical requirement for delicate or heavy panel goods, even when traveling on inclined roads up to a 5% slope.

Advantages & Benefits

The primary benefit is dramatically reduced loading time, translating to higher trailer and dock turnaround efficiency. The integrated load securing provides enhanced cargo safety and integrity during transport, reducing the risk of damage and the need for additional manual securing methods like straps or blocks. The double-deck configuration allows for optimal space utilization within the trailer cube when handling mixed-height goods. This turnkey solution streamlines the entire outbound process from dock to highway.

Implementation Considerations

This is a dedicated trailer solution; the trailers must be permanently modified with the Ancra system, making them specialized assets not suitable for general freight. The system's effectiveness is dependent on compatible automated loading equipment at the shipping dock. The solution appears highly customized for specific cargo types (e.g., flooring panels), implying that its design parameters (deck height, securing mechanism) are optimized for a particular product profile and may not be universally applicable without re-engineering.

Use Cases & Applications

Ideal For

This technology is ideal for manufacturers or distributors of specific, high-volume products like building materials (flooring, panels, sheets) that are palletized in mixed heights and shipped on dedicated routes using a company's own or contracted fleet of specialized trailers.

Performance Metrics

The source provides explicit performance data: loading time of just 3 minutes for a 13.5-meter long trailer. The load securing capability is qualified by its performance on roads with a 5% slope. The "one-shot" loading capability is a key throughput metric.

Conclusion

The AncraSystems Double Deck Trailer Chain Track System represents a highly specialized and effective solution for automating the final link in the warehouse outbound chain: loading goods into the transport vehicle. By moving automation inside the trailer itself and combining it with intelligent load locking, it solves both the speed and safety challenges of shipping delicate, mixed-load pallets. While its application is niche—requiring dedicated, modified trailers and compatible loading docks—for businesses within that niche, such as building material distributors, it offers transformative benefits in efficiency, cargo safety, and operational scalability. It exemplifies a deep vertical integration of material handling technology tailored to a specific logistics challenge.