AutoStore CarouselAI: AI-Powered Robotic Picking Module

⚡Quick Facts

Technology Performance Metrics

⭐Key Features

✨Benefits

🎯Applications

📝Detailed Information

Technology Overview

AutoStore CarouselAI represents a significant evolution in cube storage automation, introducing artificial intelligence directly into the robotic picking process on the grid. This technology moves beyond traditional storage and retrieval, addressing the critical challenge of automated piece picking from bins within the dense AutoStore system. By integrating AI-supported gripping and real-time learning, CarouselAI enables fully autonomous, high-speed picking of a wide variety of SKUs. It is specifically designed for demanding environments like e-commerce and retail, where picking accuracy, speed, and labor efficiency are paramount. When orchestrated by Dematic's system software, it transforms the AutoStore grid into a cohesive, high-performance picking engine.

How It Works

Core Principles

The core principle involves deploying an AI-equipped robotic picking module that operates autonomously on the AutoStore grid. It uses computer vision and machine learning to identify, grasp, and pick items directly from the inventory bins, learning and adapting its grip strategies in real-time based on the vast array of SKUs it encounters.

Key Features & Capabilities

AI-Supported Gripping and Real-Time Learning is the cornerstone feature. Unlike pre-programmed robots, CarouselAI can handle an extensive and changing SKU mix without manual reprogramming for each item, as its AI learns and adapts on the fly.

Full Autonomy on the Grid means the module performs the complete pick cycle—travel, identification, grasping, and delivery—without human intervention, turning the storage grid into a direct source of picked items.

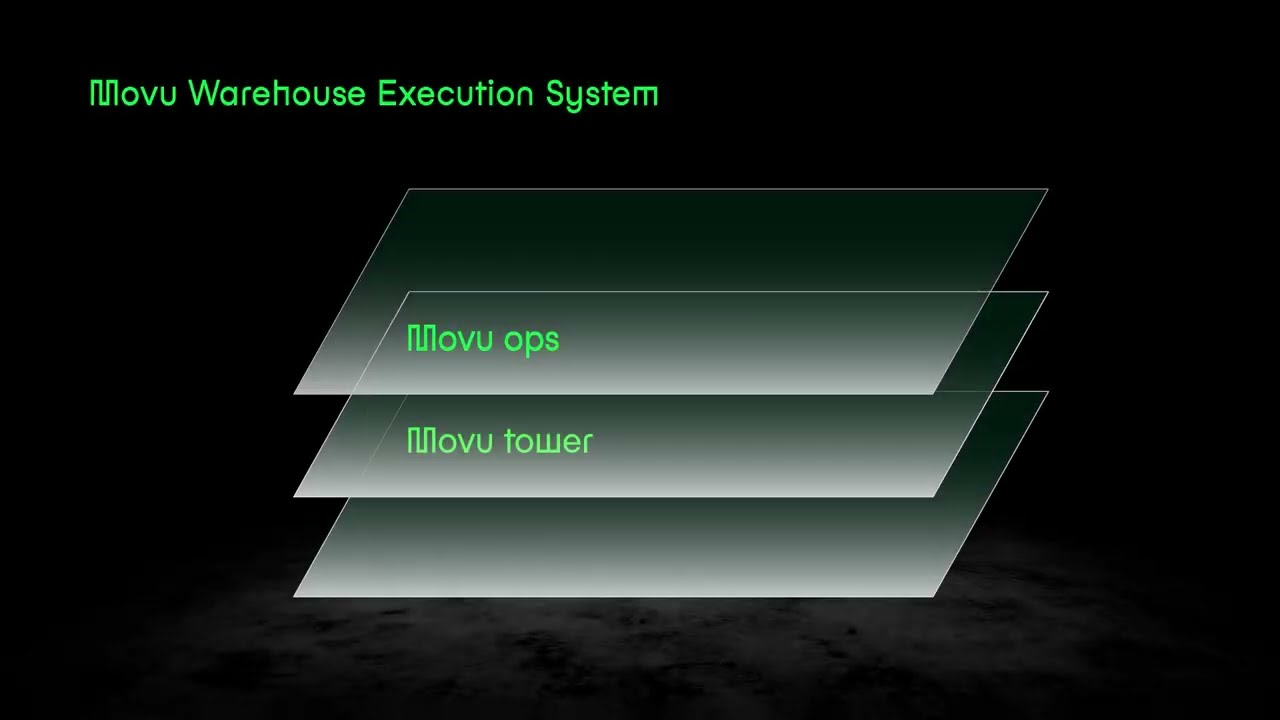

System Integration as a Force Multiplier highlights that CarouselAI is not a standalone unit. Its true power is realized when integrated into a Dematic-orchestrated ecosystem, where it works in concert with other robots, people, and software to maximize overall throughput and efficiency.

Advantages & Benefits

The primary advantage is a substantial reduction in picking errors due to the precision and consistency of AI-driven vision and gripping, leading to higher order accuracy and reduced returns.

It delivers significantly increased throughput by automating one of the most labor-intensive and time-consuming steps in the fulfillment process—piece picking—and performing it at high speed, 24/7.

The technology directly addresses labor challenges by reducing the manual workload associated with picking, allowing human workers to focus on higher-value tasks and making operations more resilient to labor shortages.

Implementation Considerations

Implementation requires a comprehensive system integration effort, as CarouselAI is designed to be part of a larger Dematic-orchestrated solution. This involves software integration, workflow redesign, and potentially significant upfront planning.

The complexity of deploying AI and robotics in the confined, high-density environment of an AutoStore grid necessitates specialized expertise and careful testing to ensure reliability and avoid grid congestion.

The total cost of ownership includes not only the robotic modules but also the AI software licenses, integration services, and potential upgrades to the overall warehouse control infrastructure.

Use Cases & Applications

Ideal For

This technology is ideal for e-commerce retailers, omnichannel operations, and third-party logistics (3PL) providers that utilize AutoStore and face challenges with high order volumes, immense SKU variety, and intense pressure on picking operations with limited labor availability.

Performance Metrics

While specific numerical metrics (e.g., picks per hour) are not provided in the given text, the content emphasizes qualitative performance gains: fewer errors, more throughput, and less manual load. The high-speed capability and ability to handle a wide SKU variety are key performance indicators.

Conclusion

AutoStore CarouselAI marks a pivotal step towards fully automated, intelligent fulfillment within dense storage systems. By bringing AI-powered dexterity directly to the point of storage, it solves a critical bottleneck in modern logistics. For operations already using or considering AutoStore that are grappling with labor-intensive picking, high error rates, or the need for greater speed, CarouselAI offers a compelling path forward. Its value is maximized when implemented as part of a holistically orchestrated system, such as one provided by Dematic, making careful partner selection and system design essential for success.

📦Related Projects

Kesko Helsinki Micro-Fulfillment Center (MFC)

Kesko deployed Finland's first grocery micro-fulfillment center featuring a Dematic AutoStore system in a chilled environment, doubling daily volumes and enabling 6-hour delivery.

South West Healthcare Warrnambool Regional Logistics Distribution Centre

South West Healthcare deployed a Dematic AutoStore system to boost inventory capacity by 500% for its regional medical supply network, storing 6-8 weeks of stock in a reduced footprint.

Notions Marketing Distribution Center with Dematic CMMS - Grand Rapids

A 75-year-old distribution company transformed maintenance operations with Dematic CMMS, reducing reactive repairs by 50% while managing extensive conveyor and sorter networks for big-box retail fulfillment.