Cantilever Racking

Cantilever racking uses horizontal arms extending from vertical columns to store long, bulky, or irregularly shaped items without front column obstruction, ideal for lumber, pipes, furniture, and sheet materials.

Cantilever Racking Overview

System Features

- •Open Front DesignNo front uprights

- •Adjustable ArmsVertical adjustment

- •Long Item StorageLumber, pipes, steel

- •Heavy-DutyUp to 5,000 lbs/arm

Arm Types

- •Straight ArmsStandard horizontal

- •Inclined ArmsPrevent rolling

- •Pipe ArmsTubular design

- •12-48 inchesArm lengths

Applications

- •Lumber YardsWood products

- •Metal DistributorsPipes and steel

- •Furniture WarehousesBulky items

- •Building SupplyConstruction materials

Key Benefits

- •Unobstructed AccessFull-length access

- •50-70% Bettervs. floor storage

- •Flexible ConfigurationAdjustable heights

- •Reduced DamageBetter protection

Configuration

- •Single-SidedWall-mounted

- •Double-SidedFreestanding

- •Height: 8-20+ ftVertical space

- •Indoor/OutdoorVarious finishes

Future Trends

- •Load SensorsReal-time monitoring

- •RFID IntegrationAuto tracking

- •Advanced MaterialsLighter, stronger

- •Automated CranesRobotic loading

How Cantilever Racking Works

The structural design consists of vertical columns (towers) anchored to the floor, with horizontal arms that bolt onto the columns at adjustable heights. The columns are typically I-beam or C-channel construction designed to resist the bending forces created by cantilevered loads extending outward from the support structure. Base plates at the bottom of each column distribute loads to the floor and provide stability, while bracing between columns (typically at the rear) adds structural rigidity and prevents lateral movement. The arms themselves are engineered to support specific load capacities based on their length, cross-section, and material properties.

Arm configuration varies based on the products being stored and operational requirements. Single-sided cantilever has arms extending from one side of the columns, typically used against walls or where access is needed from only one direction. Double-sided cantilever has arms extending from both sides of the columns, maximizing storage density in open floor areas where access from both sides is possible. The arm spacing (vertical distance between arm levels) is adjustable to accommodate different product heights, with typical adjustments in 3-4 inch increments. This adjustability allows facilities to optimize space utilization as product mix changes over time.

Load capacity varies significantly based on arm length, arm design, and column strength. Light-duty systems support 500-1,000 pounds per arm for retail or light industrial applications. Medium-duty systems handle 1,000-2,500 pounds per arm for general warehouse use. Heavy-duty systems support 2,500-5,000+ pounds per arm for industrial applications like steel storage or heavy lumber. The load rating decreases as arm length increases, as longer arms create greater bending moments at the column connection. Facilities must carefully match arm capacity to actual loads and ensure that operators understand and respect load limits to maintain safety.

Material handling typically involves forklifts with specialized attachments for long loads, though cranes, overhead hoists, or manual handling may be used depending on product weight and dimensions. Side-loading forklifts are particularly effective for cantilever applications, as they can approach the racking from the side and place long items directly onto the arms without needing to turn. Standard forklifts with extended forks or carpet poles can also be used, though they require more aisle space for maneuvering long loads. The aisle width must accommodate the longest items being stored plus adequate clearance for safe forklift operation—typically 16-24 feet for standard forklifts handling long materials.

Key Benefits

The primary advantage of cantilever racking is unobstructed front access that enables efficient loading and retrieval of long or bulky items. Unlike traditional pallet racking where front columns limit the length of items that can be stored, cantilever arms extend freely from the support structure, accommodating items of virtually any length. This open design eliminates the need to maneuver long items between columns or through narrow openings, reducing handling time and minimizing the risk of product or rack damage during loading operations.

Versatility for irregular items makes cantilever racking valuable for operations managing diverse product dimensions. The adjustable arm heights accommodate items of varying thickness or diameter, while variable arm lengths support different product lengths within the same system. This flexibility is particularly important for operations like lumber yards, steel service centers, or furniture warehouses where product dimensions vary significantly across the inventory. The ability to reconfigure arm positions as product mix changes provides long-term adaptability without major reinvestment.

Improved product visibility and accessibility results from the open front design that allows operators to see stored items clearly and access them directly. Unlike enclosed storage systems where products may be hidden behind other items, cantilever racking presents inventory openly for easy identification and retrieval. This visibility improves inventory management, order picking accuracy, and stock rotation by making it easy to see what's available and where it's located. The direct access also simplifies quality inspection and damage assessment without requiring product removal.

Space utilization improves compared to floor stacking or block storage of long items. By storing products vertically on multiple arm levels (typically 3-6 levels), cantilever racking maximizes use of available ceiling height while maintaining organized, accessible storage. The vertical storage prevents the unstable stacks and safety hazards associated with floor-stacked long materials, while the structured organization improves space efficiency and reduces the floor area required for the same inventory volume.

Common Applications

Lumber yards and building materials represent a major application for cantilever racking, storing dimensional lumber, plywood, OSB, molding, and other wood products. The open front access enables efficient loading and retrieval of lumber bundles using forklifts or overhead cranes, while the adjustable arms accommodate varying lumber dimensions from 2x4s to large beams. The outdoor-rated systems with galvanized or powder-coated finishes withstand weather exposure in uncovered lumber yards, providing durable storage for years of service.

Metal service centers and steel distributors use heavy-duty cantilever racking for storing steel bars, pipes, tubing, sheet metal, and structural steel. The high load capacities (2,500-5,000+ pounds per arm) support the weight of metal products, while the long arm lengths (up to 48+ inches) accommodate standard steel lengths. The open design enables side-loading forklifts to efficiently place and retrieve materials, critical for operations where throughput and handling efficiency directly impact profitability.

Furniture warehouses and manufacturers leverage cantilever racking for storing sofas, mattresses, tables, cabinets, and other furniture items that don't fit standard pallet dimensions. The adjustable configuration accommodates the varying sizes and shapes of furniture products, while the open access prevents damage during loading and retrieval. Many furniture operations use carpeted or padded arms to protect products from scratches or marks, adding value through damage prevention.

Plumbing and HVAC distributors store pipes, ductwork, conduit, and other long materials on cantilever racking. The organized storage by size and type improves order picking efficiency and inventory management, while the vertical storage maximizes space utilization in facilities with limited floor area. The easy access enables quick retrieval of specific items without disturbing other stored materials, important for operations fulfilling customer orders throughout the day.

Carpet and flooring retailers use cantilever racking for storing carpet rolls, vinyl rolls, padding, and other rolled goods. The horizontal arm storage supports rolls without crushing or deforming them, while the open front enables easy inspection of patterns and colors. The adjustable arms accommodate rolls of varying diameters, from thin padding to large carpet rolls, providing flexible storage for diverse inventory.

Implementation Considerations

Successful cantilever implementation requires careful load analysis to ensure that arm and column capacities match actual product weights and dimensions. Facilities must determine the maximum load per arm, total load per column, and floor load to specify appropriate system components. Overloading is a leading cause of cantilever failures and can result in catastrophic collapse, making accurate load assessment and clear capacity labeling essential for safe operation.

Floor capacity must support the concentrated loads at column base plates, typically 4,000-8,000 PSF for medium-duty systems and higher for heavy-duty applications. Older facilities or those with suspended slabs may require floor reinforcement or load distribution measures to safely support cantilever systems. A structural engineer should evaluate floor capacity before installation, particularly for heavy-duty systems or tall configurations that create high concentrated loads.

Aisle width planning must account for the longest items being stored plus adequate clearance for safe forklift operation. Standard forklifts handling 20-foot materials typically require 20-24 foot aisles, while side-loading forklifts can operate in narrower aisles (12-16 feet) by approaching from the side. The turning radius of material handling equipment and the maneuvering space needed for long loads must be considered during layout design to ensure efficient, safe operation.

Seismic considerations are particularly important for cantilever racking due to the cantilevered loads that create significant lateral forces during earthquakes. Facilities in seismic zones require engineered designs with proper bracing, anchoring, and structural calculations that account for earthquake forces. Professional engineering and installation by experienced contractors ensure compliance with local building codes and industry standards like RMI (Rack Manufacturers Institute) guidelines.

Best Practices

Product organization strategies should group similar items by size, type, or velocity to improve operational efficiency. Fast-moving items should be positioned in the most accessible locations near shipping areas, while slower-moving products can occupy more remote positions. Organizing by size (shortest to longest, lightest to heaviest) simplifies inventory management and helps operators quickly locate specific items. Clear labeling and signage identifying product types, sizes, and locations improves picking accuracy and reduces search time.

Load distribution should be managed to prevent overloading individual arms or columns while maintaining balanced loads across the system. Heavier items should be stored on lower arms to lower the center of gravity and improve stability, while lighter products can occupy upper levels. Uniform loading across arms at the same level prevents uneven stress on columns and improves structural performance. Operators should be trained to distribute loads properly and avoid concentrating heavy items in specific areas.

Safety features including column protectors, end-of-aisle guards, and load capacity signage help prevent damage and ensure safe operation. Arm stops or backstops prevent items from sliding off the rear of arms, particularly important for round items like pipes or rolls. Safety netting or wire mesh backing can be installed on double-sided systems to prevent items from falling through to the opposite side. Proper lighting in storage areas improves visibility and reduces the risk of accidents during loading and retrieval.

Regular inspections identify damage or deterioration before it compromises safety. Monthly visual inspections should check for bent arms, damaged columns, loose connections, and overloaded positions. Annual professional inspections by qualified rack safety experts provide comprehensive assessments and ensure compliance with industry standards. Any damaged components should be repaired or replaced immediately, as compromised structural integrity can lead to catastrophic failures affecting multiple storage positions.

Measuring Success

Key performance indicators for cantilever racking include space utilization (vertical storage efficiency), load capacity utilization (percentage of rated capacity being used), damage incidents per month, and picking productivity (items retrieved per hour). These metrics help operations evaluate whether the system is being used effectively and safely while supporting operational requirements.

Return on investment typically materializes over 2-4 years through improved space utilization, better organization, reduced product damage, and improved operational efficiency. The vertical storage capability often enables facilities to store 2-3 times more inventory in the same floor space compared to floor stacking, deferring or eliminating the need for facility expansion. The organized storage reduces search time and improves picking productivity, lowering labor costs and improving customer service.

Safety performance should show reduced accidents and product damage compared to floor stacking or unorganized storage of long materials. The structured storage eliminates the unstable stacks and trip hazards associated with floor-stored long items, while the clear aisles improve forklift safety. Tracking damage incidents, near-miss events, and rack damage helps identify areas for improvement in operator training, load management, or system protection.

Product damage rates should decrease compared to floor stacking, as the organized storage on arms prevents the crushing, bending, or scratching that often occurs when long items are stacked on top of each other. The easy access also reduces handling damage during retrieval, as operators can remove specific items without disturbing other stored materials.

By implementing cantilever racking with careful attention to load capacity, floor conditions, and safety management, facilities can create efficient, organized storage for long, bulky, or irregular items. The specialized design and proven performance make cantilever racking an essential tool for lumber yards, metal distributors, furniture operations, and any facility managing products that exceed standard pallet dimensions.

🔧Related Technologies (6)

Roll Out Cantilever Rack: Drawer-Access Storage for Long Materials

byOthers

Cantilever Racking Systems: Storage for Long, Bulky & Heavy Items

byAtlantic Rack

Dark Warehouse: Fully Automated Warehouse Operations

byAddverb

Live Storage Systems: Gravity-Flow High-Density Storage

byAR Racking

MIX: All-round Goods-to-Person Picking Solution

byMushiny

Autopicker: AI-Powered Mobile Picking Robot

byBrightpick

📚Related Storage Topics

About This Topic

📁Related Projects(6)

MULTIFLEX Pallet Warehouse: High-Density Frozen Storage

MFI (implied contractor)

Bastian Solutions Corporate Profile: Toyota Advanced Logistics

Bastian Solutions

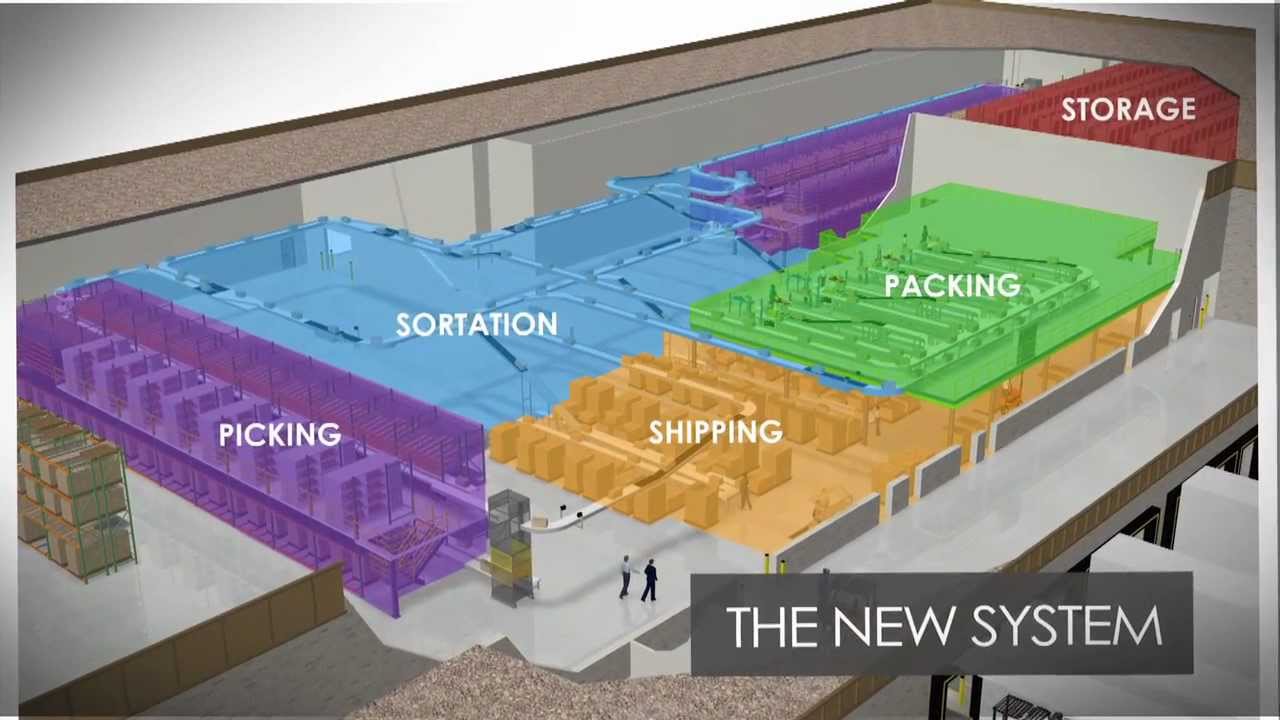

Amway Midwest Regional Service Center, Ada

Bastian Solutions

Roche Diagnostics Indianapolis Distribution Center

Bastian Solutions

Addverb 3PL Omnichannel Fulfillment Center

Addverb

SEW-EURODRIVE Bruchsal Electronics Plant

GEBHARDT Intralogistics Group

🏢Related Suppliers(3)

Exotec

Elegant Solutions to Simplify Logistic Operations

Symbotic

AI-Powered Warehouse Automation Systems

Boston Dynamics

Advanced robotics company developing mobile robots for industrial automation and logistics applications.