Pick-to-Light Systems

Pick-to-light systems use illuminated displays at storage locations to guide warehouse workers to the correct items and quantities, dramatically improving picking speed and accuracy.

Core Technology

- • LED light displays

- • Digital quantity indicators

- • Confirmation buttons

- • Visual guidance system

- • Real-time communication

Hardware Components

- • LED modules

- • Control systems

- • Network infrastructure

- • Barcode scanners

- • Mobile workstations

Applications

- • Order fulfillment

- • Batch picking

- • Multi-line orders

- • Fast-moving goods

- • Pharmaceutical distribution

Benefits

- • Visual guidance

- • Reduced search time

- • Higher accuracy

- • Faster training

- • Batch processing

Implementation

- • Light module installation

- • Zone configuration

- • WMS integration

- • Network setup

- • Worker training

Considerations

- • Pick face mapping

- • Power requirements

- • Maintenance needs

- • System reliability

- • Scalability planning

Key Performance Metrics

How Pick-to-Light Systems Work

In a typical pick-to-light operation, the Warehouse Management System (WMS) transmits order information to the pick-to-light controller, which activates the appropriate light modules throughout the picking zone. Each light module consists of bright LED displays showing the quantity to pick, along with a confirmation button that workers press after completing each pick. The system guides pickers through orders sequentially, illuminating the next location only after the previous pick is confirmed.

The technology operates on a simple but powerful principle: visual guidance is faster and more intuitive than reading instructions from paper or screens. Workers can quickly scan their assigned zone, immediately identifying lit locations without searching through lists or consulting devices. This direct visual connection between instruction and action creates a natural, efficient workflow that requires minimal training and delivers consistent performance.

Modern pick-to-light systems integrate seamlessly with warehouse control systems, providing real-time inventory updates, order tracking, and performance monitoring. As workers confirm picks, the system instantly updates inventory records, validates order completion, and triggers downstream processes like packing and shipping.

Key Benefits

The primary advantage of pick-to-light systems is dramatic improvement in picking speed. Workers can typically achieve 300-600 picks per hour with pick-to-light compared to 100-200 picks per hour with paper-based picking. This productivity gain stems from eliminating the time spent reading pick lists, searching for locations, and verifying item information.

Accuracy rates with pick-to-light systems typically exceed 99.9%, virtually eliminating the picking errors that plague manual operations. The combination of visual guidance and confirmation buttons creates a closed-loop system that catches mistakes before they become costly mis-shipments. The bright, unmistakable light displays leave no room for confusion about which location to pick from or how many items to collect.

Training time drops dramatically with pick-to-light technology. New workers can achieve full productivity within hours rather than the days or weeks required to learn traditional picking methods. The intuitive interface requires no language skills or complex procedures—workers simply follow the lights and press buttons to confirm picks.

The technology also delivers ergonomic benefits by allowing workers to maintain better posture and reduce eye strain. Instead of constantly looking down at paper lists or handheld screens, pickers can keep their heads up and maintain natural body positions while working, reducing fatigue and workplace injuries.

Pick-to-Light Systems: Accuracy and Efficiency for Manufacturing

Vendor: Banner Engineering

System Components

A complete pick-to-light system consists of several integrated components working together. Light modules mounted at each pick location feature bright LED displays, typically showing two or three digits for quantity indication. These modules include confirmation buttons—usually large, easy-to-press switches that provide tactile feedback when activated. Many modern modules use multi-color LEDs to convey additional information through color coding, such as red for priority orders or yellow for special handling requirements.

The control system serves as the brain of the operation, managing communication between the WMS, light modules, and other system components. This controller processes order information, determines optimal picking sequences, tracks completion status, and provides real-time performance data. Advanced systems use distributed intelligence, with processing power distributed across multiple controllers to ensure reliability and scalability.

Power and communication infrastructure connects all light modules to the control system. Modern installations typically use bus-based wiring that daisy-chains modules together, reducing installation complexity and cost compared to individual wiring for each module. Some newer systems employ wireless communication, eliminating wiring altogether and providing greater flexibility for reconfiguration.

Integration interfaces connect the pick-to-light system to the WMS and other warehouse systems, ensuring seamless data flow and coordinated operations. These interfaces handle order downloads, inventory updates, and performance reporting, creating a unified fulfillment ecosystem.

Implementation Strategies

Successful pick-to-light implementations require careful planning and design. Zone design is critical—pick-to-light works best in dedicated zones with relatively stable product assignments. Most operations implement pick-to-light in their fastest-moving SKU areas, where the high pick frequency justifies the technology investment and delivers maximum return.

Slotting optimization becomes even more important with pick-to-light systems. Products should be positioned based on velocity, with the fastest movers in the most accessible locations. The system's speed advantages are maximized when workers can maintain efficient picking paths without excessive reaching, bending, or traveling.

Batch picking strategies often pair well with pick-to-light technology. Workers can pick multiple orders simultaneously, with the system displaying the total quantity needed across all orders in the batch. This approach multiplies the productivity gains from pick-to-light while maintaining high accuracy through the confirmation process.

Order release timing should be coordinated to maintain steady workflow without overwhelming the system or creating picker congestion. The WMS should release orders in waves that balance workload across zones and align with downstream packing and shipping capacity.

Pick-to-Light Systems: Light-Directed Order Picking

Vendor: Others

Best Practices

To maximize pick-to-light effectiveness, consider these proven strategies. Regular maintenance of light modules ensures consistent performance—burned-out LEDs or sticky buttons can disrupt workflow and reduce accuracy. Establish preventive maintenance schedules that include cleaning displays, testing buttons, and verifying communication integrity.

Performance monitoring at both the system and worker level helps identify training needs and process improvements. Track metrics like picks per hour, error rates, and confirmation response times to understand where the operation excels and where it needs attention. Modern systems provide detailed analytics that reveal patterns and opportunities for optimization.

Dynamic slotting adjusts product locations based on changing velocity patterns, ensuring that the fastest movers always occupy the most efficient pick positions. The WMS should continuously analyze pick frequency and recommend slotting changes to maintain optimal performance.

Backup procedures should be established for system outages or maintenance periods. While pick-to-light systems are highly reliable, having contingency plans ensures that operations can continue during unexpected disruptions.

Integration with Other Technologies

Pick-to-light systems often work in conjunction with complementary technologies. Goods-to-person systems can deliver items to pick-to-light zones, creating highly efficient hybrid operations where automation handles transport while pick-to-light guides the picking process. This combination is particularly effective for small-item fulfillment.

Put-to-light systems frequently pair with pick-to-light in batch picking operations. Workers use pick-to-light to collect items for multiple orders, then use put-to-light at sorting stations to distribute items into individual order containers. This integrated approach maximizes efficiency throughout the fulfillment process.

Voice picking can complement pick-to-light in operations with diverse picking requirements. Pick-to-light handles high-density zones with many SKUs, while voice picking manages full-pallet picks or items in less dense areas. This hybrid approach optimizes technology deployment based on specific operational needs.

Technology Variations

Several variations of pick-to-light technology address specific operational requirements. Pick-to-light carts bring the technology to the picker rather than requiring dedicated zones. These mobile solutions work well in operations with variable product locations or limited space for permanent installations.

Wireless pick-to-light systems eliminate wiring requirements, providing flexibility for seasonal operations or frequently reconfigured facilities. Battery-powered modules can be easily relocated as product assignments change, though battery management becomes an additional operational consideration.

Smart glasses and augmented reality systems represent the next evolution of pick-to-light technology, projecting visual guidance directly into the worker's field of vision. While still emerging, these technologies promise to combine pick-to-light's visual guidance with the mobility of voice picking.

Measuring Success

Key performance indicators for pick-to-light systems include picks per hour per worker, picking accuracy rates, order cycle time, and system uptime. These metrics help assess technology effectiveness and identify optimization opportunities.

Return on investment typically materializes within 18-36 months through labor savings, reduced error costs, and increased throughput capacity. The combination of higher productivity and improved accuracy creates compelling economics for operations with sufficient pick volume to justify the capital investment.

Worker satisfaction often improves with pick-to-light implementation, as the technology reduces physical and mental strain while making jobs easier to learn and perform. This can translate into lower turnover rates and reduced training costs.

By implementing pick-to-light technology with careful attention to zone design, slotting optimization, and performance monitoring, warehouses can transform their picking operations from labor-intensive bottlenecks into efficient, accurate processes that support rapid order fulfillment and business growth. The technology's proven track record and continuous evolution ensure it remains a valuable tool in modern warehouse operations.

🔧Related Technologies (6)

Momentum WES: Next-Generation Warehouse Execution and Control

byHoneywell Intelligrated

Pick2Pallet: Integrated Pick-to-Light System for Pallet Jacks

byThe Raymond Corporation

Rapido Pick to Light System: Paperless Warehouse Picking

byAddverb

Pick-to-Light Systems: Accuracy and Efficiency for Manufacturing

byBanner Engineering

Pick-to-Light Systems: Light-Directed Order Picking

byOthers

Box-IT: Ergonomic Goods-to-Person Workstation

byAddverb

📚Related Picking Topics

About This Topic

📁Related Projects(6)

Ariat Wholesale Footwear & Apparel Order Fulfillment Center

EuroSort

Bastian Solutions Corporate Profile: Toyota Advanced Logistics

Bastian Solutions

CNH Industrial Indianapolis Distribution Center

Bastian Solutions

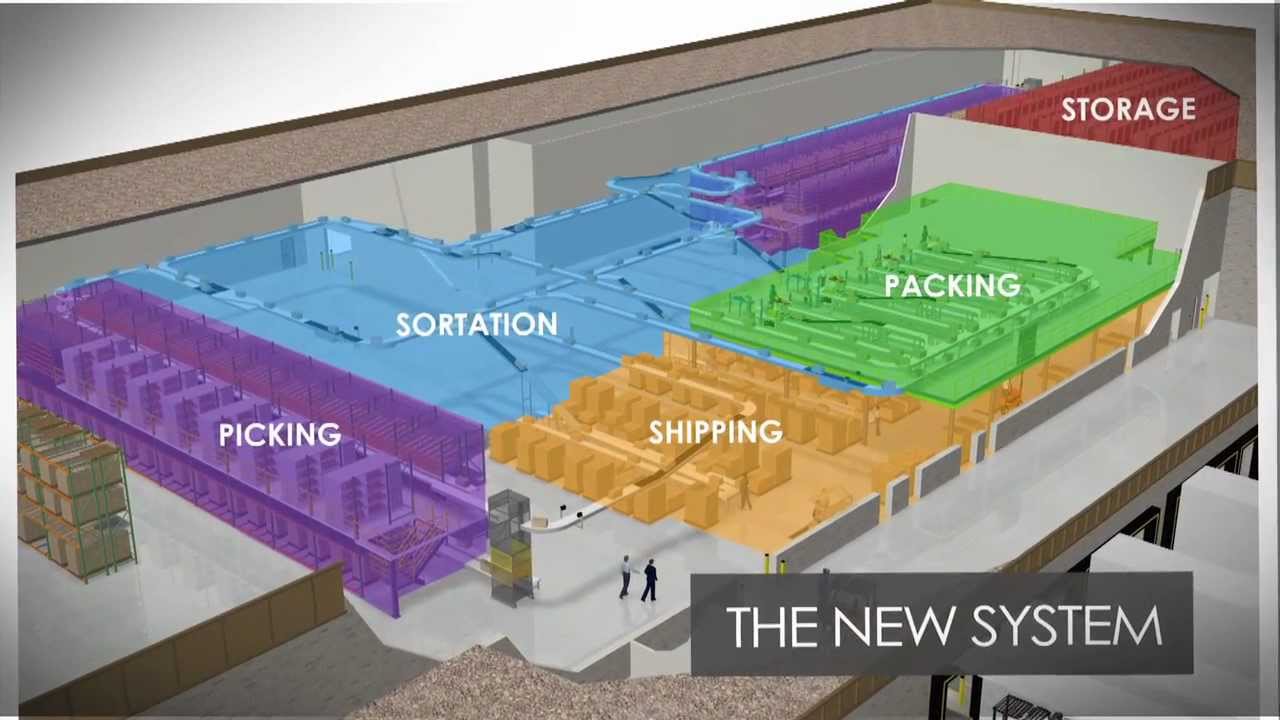

Amway Midwest Regional Service Center, Ada

Bastian Solutions

Roche Diagnostics Indianapolis Distribution Center

Bastian Solutions

Addverb 3PL Omnichannel Fulfillment Center

Addverb