Third-Party Logistics (3PL)

Third-party logistics providers operate warehouses and fulfillment centers for multiple clients, requiring flexible automation solutions that can handle diverse products, varying service levels, and rapid client onboarding while maintaining operational efficiency.

📦 Third-Party Logistics (3PL) Ecosystem

Operations Profile

- •Multi-client operations

- •Diverse product types

- •Flexible capacity

- •Value-added services

Key Challenges

- •Client churn & onboarding

- •Capacity utilization

- •System integration complexity

- •Cost allocation accuracy

Storage Solutions

- •Flexible racking systems

- •Modular AS/RS

- •Multi-temperature zones

- •Scalable shuttle systems

Automation Technologies

- •AMRs (flexible deployment)

- •Modular conveyors

- •Goods-to-person systems

- •Sortation systems

Software Systems

- •Multi-tenant WMS

- •Billing & cost allocation

- •Client portals

- •EDI integration

Value-Added Services

- •Kitting & assembly

- •Labeling & packaging

- •Returns processing

- •Quality inspection

🌐 Industry Overview

Third-party logistics (3PL) providers operate warehouses and fulfillment centers on behalf of multiple clients, offering services ranging from basic storage to complete supply chain management. This sector is characterized by extreme diversity—a single facility might handle consumer electronics for one client, apparel for another, and industrial parts for a third. The business model requires operational flexibility, rapid client onboarding, and the ability to scale services up or down based on client needs.

The 3PL industry has grown dramatically with e-commerce expansion and companies' desire to focus on core competencies rather than logistics operations. Major players range from global logistics giants operating millions of square feet to regional specialists serving specific industries or geographies. Competition is intense, with clients demanding lower costs, better service, and increasing technology capabilities while maintaining thin profit margins typical of logistics services.

🏭 Warehouse Operations Characteristics

3PL facilities must accommodate multiple clients with different requirements within the same building. This creates unique operational challenges—inventory must be segregated by client, picking processes may vary by customer, and service level agreements (SLAs) differ significantly. Some clients require same-day fulfillment while others accept 48-hour processing. Product types range from small e-commerce items to industrial equipment, often within the same facility.

Flexibility is paramount. Client mix changes frequently as contracts are won and lost, seasonal clients ramp up and down, and business volumes fluctuate. The facility must adapt quickly—reconfiguring space allocation, adjusting labor levels, and modifying processes without disrupting service to other clients. This dynamic environment makes long-term planning difficult and requires automation solutions that can be reconfigured or repurposed.

Billing complexity adds operational overhead. 3PLs must track activities by client for billing purposes—storage space utilized, orders processed, special services provided. This requires detailed data capture and reporting capabilities beyond typical warehouse operations. Accuracy is critical as billing disputes damage client relationships and impact profitability.

⚠️ Key Challenges

Client diversity creates operational complexity. Each client has different products, processes, and requirements. Standardization is difficult when one client ships full pallets to stores while another fulfills individual e-commerce orders. Trying to optimize for all clients simultaneously often results in compromises that satisfy no one fully. Balancing standardization for efficiency with customization for client satisfaction is an ongoing challenge.

Capacity utilization directly impacts profitability. Empty space doesn't generate revenue, but overcrowding creates operational inefficiencies. Seasonal clients create peaks and valleys in space requirements. Long-term contracts provide stability but limit flexibility to take on higher-margin short-term business. Forecasting capacity needs is complicated by client business volatility and competitive market dynamics.

Labor management is particularly challenging. Workforce requirements fluctuate with client volumes, which don't always align. Peak seasons vary by client—back-to-school for one, holidays for another, year-end for a third. Maintaining a skilled workforce through these fluctuations while controlling labor costs requires sophisticated planning and flexible staffing models.

🤖 Suitable Technologies

Storage Solutions: Flexible racking systems that can be reconfigured as client mix changes are essential. Adjustable pallet racking accommodates varying product sizes. Mobile racking maximizes space utilization when needed. Mezzanines add capacity without building expansion. Avoid highly specialized storage systems that can't be repurposed—3PL operations must adapt to changing client needs.

Transport Systems: AMRs provide flexibility that fixed conveyors cannot match. As client locations within the facility change, AMRs adapt without infrastructure modifications. Modular conveyor systems that can be reconfigured are preferable to permanent installations. Tugger trains and manual material handling remain important for their flexibility and lower capital requirements.

Picking Technologies: Goods-to-person systems work well for e-commerce clients with high order volumes. Voice picking and pick-to-light provide flexibility across different client operations. Put walls enable efficient multi-client batch picking. Avoid client-specific automation that can't be shared—investment must serve multiple clients to justify costs in the thin-margin 3PL business.

Software Systems: Advanced WMS with multi-client capabilities is critical. The system must segregate inventory by client, support different picking strategies, track activities for billing, and provide client-specific reporting. Integration capabilities are essential—3PLs must connect with diverse client systems (ERPs, e-commerce platforms, transportation systems). Cloud-based solutions offer advantages for client visibility and system scalability.

🎯 Technology Selection Criteria

Flexibility and scalability are paramount. Automation must accommodate changing client mix, varying product types, and fluctuating volumes. Modular systems that can be expanded incrementally or reconfigured are preferable to large fixed installations. Consider how automation will be utilized if a major client leaves—can it serve other clients or will it sit idle?

ROI calculations must account for client turnover and volume volatility. Conservative assumptions about utilization are prudent. Payback periods should be shorter than typical client contract lengths. Shared automation serving multiple clients provides better risk mitigation than client-specific solutions. Operating expense models (leasing, robotics-as-a-service) may be more appropriate than large capital investments.

Integration capabilities are critical. 3PLs must connect with numerous client systems, each with different technologies and requirements. Choose automation and software with proven integration capabilities and strong API support. Implementation time matters—3PLs need to onboard new clients quickly, so systems that can be configured rapidly provide competitive advantage.

💡 Implementation Considerations

Start with solutions that serve multiple clients rather than client-specific automation. A goods-to-person system can handle e-commerce orders for several clients more cost-effectively than dedicated automation for each. Shared resources improve utilization and spread capital costs across more revenue.

Design facilities with flexibility in mind. Use movable partitions rather than permanent walls for client segregation. Install power and data infrastructure throughout the building to support future reconfigurations. Plan for 20-30% more dock doors than currently needed—client mix changes may require different shipping patterns. Build mezzanines with future expansion in mind.

Implement robust WMS before adding physical automation. Many 3PL operational challenges stem from inadequate software rather than lack of automation. A strong WMS with multi-client capabilities, flexible picking strategies, and comprehensive reporting provides immediate benefits and creates the foundation for future automation.

Develop standardized processes that can accommodate client variations. Create service tiers (standard, expedited, premium) rather than fully custom processes for each client. This standardization enables automation while still meeting diverse client needs. Clients often accept standard processes if service levels and costs are competitive.

Change management in 3PL operations focuses on adaptability. Workers must be comfortable with changing processes, varying products, and different client requirements. Cross-training is essential—staff should be able to work across multiple client operations. Plan for 9-12 months from project start to operation for significant automation, with phased implementation that minimizes disruption to existing client operations.

Consider partnerships with automation vendors for flexible commercial models. Robotics-as-a-service, pay-per-use models, or revenue-sharing arrangements align costs with revenue better than large upfront capital investments. These models also provide upgrade paths as technology evolves, important in the fast-changing 3PL industry.

🔧Related Technologies (6)

TiltSort-Bot: Autonomous Mobile Robot (AMR) for Sortation

by Conveyco

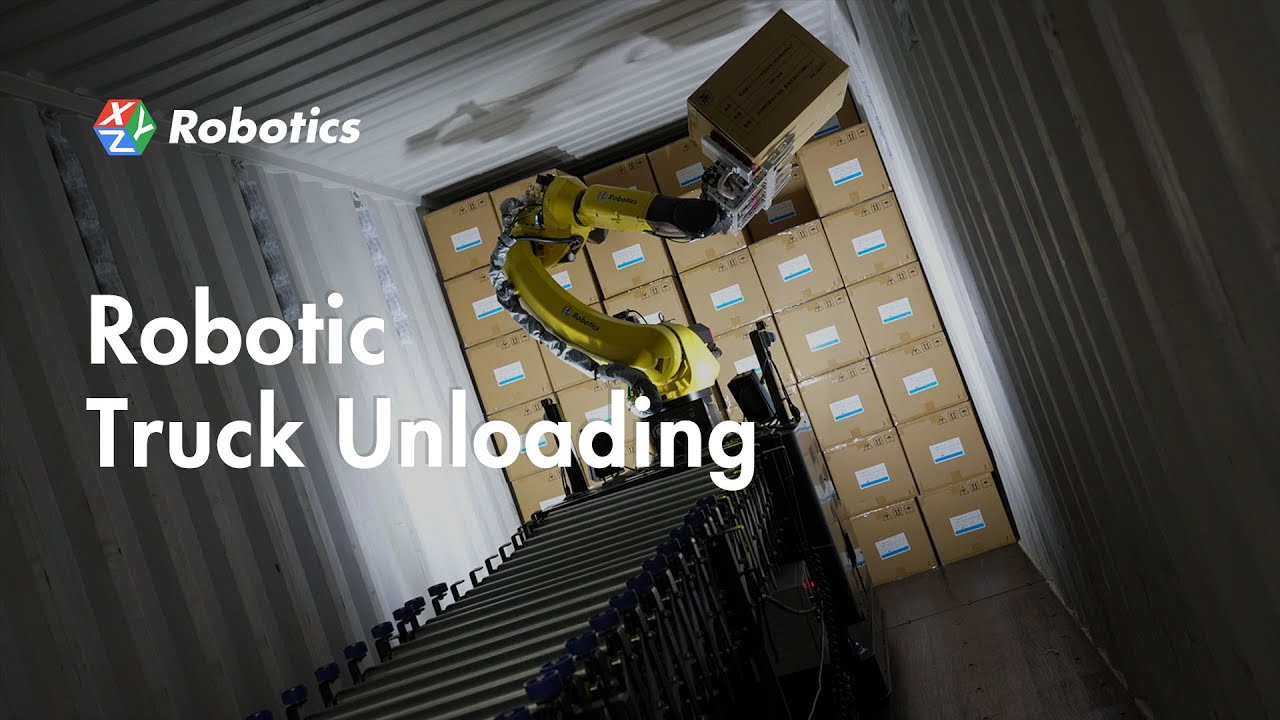

Truck Loading and Unloading AGV: Automated Trailer Handling

by Ancra Systems

LoadRunner Plus: Non-Modified ATLS for Automated One-Shot Pallet Loading & Unloading

byAncra Systems

Zippy Robotic Sorter: High-Speed AI-Powered Sortation

byAddverb

Dual Split Tray (Bomb Bay) Sorter for 3PL E-commerce

byEuroSort

Loop-Based Tilt Tray Parcel Sorter: High-Throughput Solution

byFalcon

📚Related Topics

📊Logistics & Healthcare Segments Comparison

| Segment | Characteristics | Key Challenge | Automation Focus | Implementation |

|---|---|---|---|---|

| Third-Party Logistics (3PL) | Multi-client operations, diverse products, flexible services | Client diversity and capacity utilization | Flexible, reconfigurable systems serving multiple clients | 9-12 months, modular approach |

| Parcel & Express | High-speed sortation, millions of packages daily, tight time windows | Volume volatility and speed requirements | High-speed sorters, automated tracking, DWS systems | 12-18 months, peak capacity design |

| Healthcare & Pharma | Regulatory compliance, cold chain, serialization, life-critical products | GMP/GDP compliance and traceability | Validated systems, temperature control, serialization | 18-24+ months, extensive validation |

| Wholesale B2B | Bulk orders, pallet-level shipments, customer-specific requirements | Customer diversity and inventory management | Case-picking, pallet building, route optimization | 9-12 months, customer-focused approach |

Click on segment names to view detailed information about each logistics and healthcare segment.