Pick-it-Easy Robot: Industry-Grade Robotic Picking Solution

⚡Quick Facts

Technology Performance Metrics

⭐Key Features

✨Benefits

🎯Applications

📝Detailed Information

Technology Overview

The Pick-it-Easy Robot from KNAPP is positioned as a practical, industry-grade solution designed to move robotic picking beyond conceptual showcases into real-world warehouse operations. It addresses core logistical pain points such as labor shortages, rising costs, and the need to handle an increasingly diverse and expanding SKU range. By leveraging advanced artificial intelligence and emphasizing seamless system integration, this robot aims to deliver tangible value by automating complex picking tasks that were previously difficult to automate reliably, thereby transforming order fulfillment processes.

How It Works

Core Principles

The core principle is AI-driven, adaptive robotic manipulation integrated into the broader warehouse ecosystem. The system uses artificial intelligence not just for vision and grasping, but for continuous learning and improvement, sharing knowledge across a network of robots to enhance collective performance over time.

Key Features & Capabilities

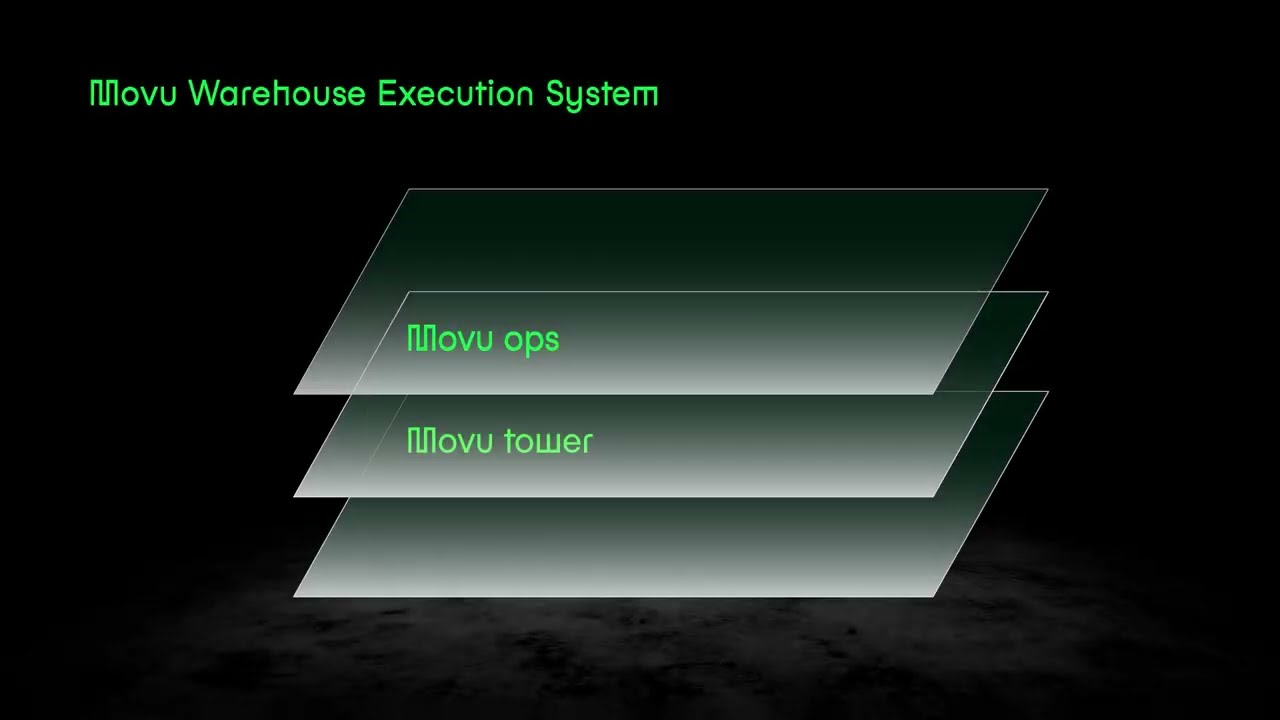

The AI-powered self-learning capability is the standout feature, allowing the system to handle a vast and growing item portfolio without extensive manual reprogramming for each new SKU. Its exceptional item handling versatility covers a broad spectrum of shapes, sizes, and materials, including delicate and transparent objects, which are traditionally problematic for automation. The network learning via cloud data creates a powerful feedback loop where the entire fleet becomes smarter based on the experience of each individual robot. Crucially, the system is built for intelligent system integration, designed to blend smoothly into existing Warehouse Execution Systems (WES) and material flow concepts, rather than operating as an isolated island of automation.

Advantages & Benefits

The primary business advantage is solving critical operational challenges related to consistent labor availability and the pressure to improve cost efficiency in the face of rising wages and e-commerce demands. It directly improves the working environment by automating repetitive and physically demanding picking tasks, allowing human workers to focus on more value-added or supervisory roles. The technology delivers superior performance and reliability for complex picking, enabling higher throughput, fewer errors, and greater process transparency compared to manual methods or less advanced automation.

Implementation Considerations

Successful implementation hinges on intelligent system integration. The robot must be seamlessly woven into the existing software architecture (WMS/WES) and physical logistics flow (conveyors, shuttle systems). Companies must consider the IT infrastructure and data strategy to support the cloud-based network learning, including data security and connectivity. The total cost of ownership should be evaluated against the gains in labor productivity, accuracy, and the ability to handle a complex and growing SKU mix.

Use Cases & Applications

Ideal For

This solution is ideal for warehouses and distribution centers across multiple industries that face high SKU complexity, labor-intensive picking, and the need for gentle, precise handling of diverse products.

Conclusion

The KNAPP Pick-it-Easy Robot represents a significant step forward in practical, AI-driven warehouse automation. It successfully addresses the skepticism around robotics being mere "fancy toys" by focusing on reliability, integration, and solving real business problems. For companies struggling with staffing, accuracy, and the complexity of modern SKUs, this technology offers a path to a more resilient, efficient, and scalable operation. Its emphasis on continuous learning and system integration ensures it can adapt and deliver increasing value over time, making it a strategic investment for forward-thinking logistics operations across a wide range of industries.

📦Related Projects

Peak Pharmacy Bolsover Distribution Center

Peak Pharmacy implemented KNAPP automation to merge three warehouses into one, automating prescription dispensing and enabling next-day delivery to 134 pharmacies across England.

Selfar SA Thessaloniki Pharmaceutical Distribution Center

Selfar SA implemented KNAPP's OSR Shuttle Evo solution for pharmaceutical wholesale distribution, achieving world-record ramp-up in one week despite COVID-19 challenges.

DSV Venlo Distribution Center

DSV commissioned KNAPP with an omnichannel fulfilment solution for their 60,000 sqm distribution centre in Venlo, handling textile and sports sectors for European supply chain centralization.