CVP Impack: Automated Packaging Solution for E-commerce

⚡Quick Facts

Technology Performance Metrics

⭐Key Features

✨Benefits

🎯Applications

📝Detailed Information

Technology Overview

The CVP Impack Automated Packaging Solution from Sparck Technologies represents a significant advancement in the automation of the final steps in e-commerce and direct-to-consumer fulfillment: packing and shipping. Designed to handle the high-volume, variable-sized parcel demands of modern online retail, this system aims to replace manual, labor-intensive packing stations with a reliable, high-speed automated process. Celebrating a century of engineering heritage in 2024, Sparck Technologies positions this solution not just as a productivity tool, but as a brand-enhancing technology that ensures every shipped parcel meets high standards of presentation and efficiency, contributing to smarter, faster, and more environmentally conscious operations.

How It Works

Core Principles

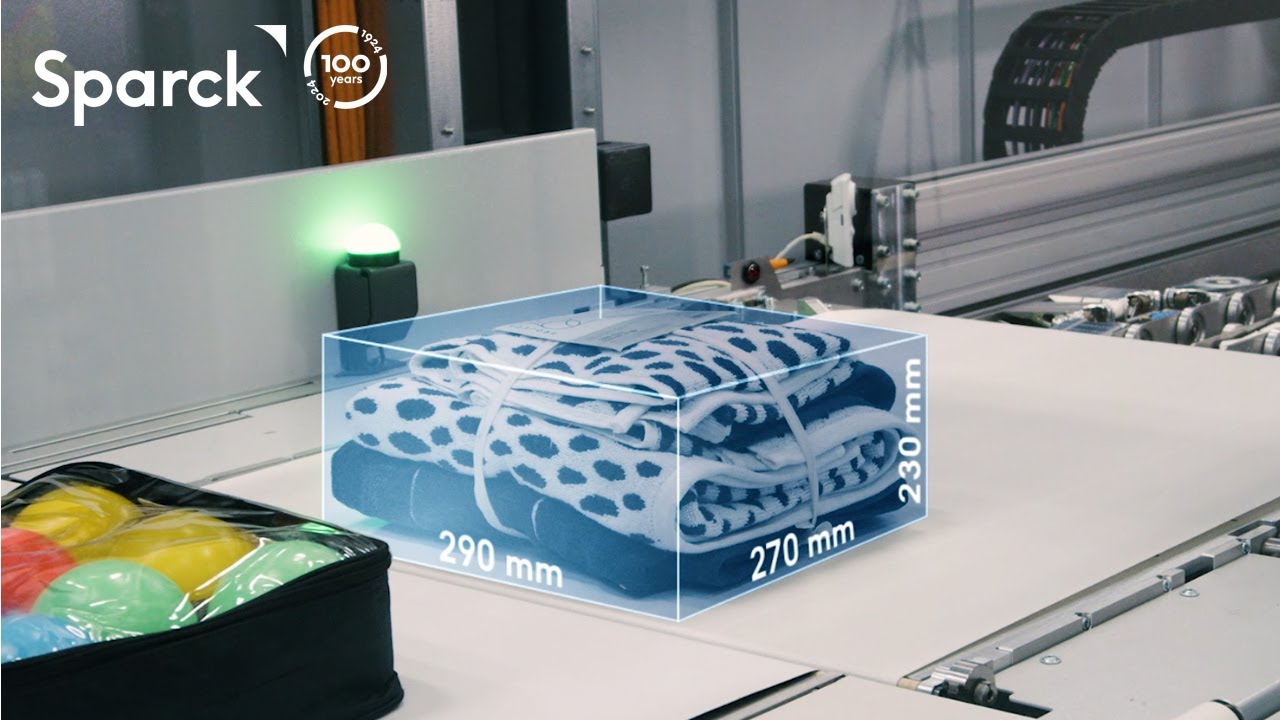

The core principle is the automated creation of right-sized parcels. The system likely automates the selection of box size or bag type, product insertion, dunnage addition, and sealing, based on the dimensions of the order contents, to optimize material usage and shipping costs.

Key Features & Capabilities

The high-speed automated throughput of up to 500 parcels per hour is a defining capability, enabling it to serve as the packing engine for large-scale fulfillment operations. The system is engineered to contribute to smarter and greener fulfillment, likely through features like right-sized packaging that reduces material waste and dimensional weight shipping charges. Its design supports a broad range of industries, indicating adaptability to different product types and packaging requirements. Being from a supplier with a century of engineering heritage, it promises market-leading reliability and performance.

Advantages & Benefits

The primary benefit is a dramatic increase in packing productivity and speed, directly addressing labor challenges and enabling scalability during peak periods. By automating a repetitive task, it also improves packing consistency and accuracy, reducing errors. The "greener" claim suggests benefits in sustainability through reduced packaging material waste and potentially lower shipping costs via optimized parcel sizing. For clients, it turns the packing process into a brand ambassador, ensuring parcels are professionally and consistently prepared. The solution helps operations become more resilient and scalable to handle growing e-commerce volumes.

Implementation Considerations

Implementing a fully automated packing system like the CVP Impack is a significant capital investment suited for high-volume facilities. It requires seamless integration with the upstream picking/sortation systems and the Warehouse Management System (WMS) for order data. The physical footprint of the machinery, along with utilities (power, compressed air, network), must be accommodated. Product compatibility must be assessed to ensure the system can handle the size, weight, and fragility of the items being packed. Ongoing maintenance and technical support are crucial for sustained high performance.

Use Cases & Applications

Ideal For

This solution is ideal for large e-commerce retailers, high-volume 3PLs, and wholesalers or manufacturers with significant direct-to-consumer shipping operations that need to automate their last manual bottleneck before shipping.

Conclusion

The CVP Impack Automated Packaging Solution from Sparck Technologies offers a powerful answer to the pressing need for speed and efficiency in the final meter of the e-commerce fulfillment race. For operations constrained by manual packing limits, implementing such a system can unlock new levels of throughput, consistency, and cost control. While the investment is substantial, the potential returns in labor savings, scalability, improved shipping economics, and enhanced customer experience make it a compelling strategic investment for high-volume players aiming to lead in the competitive world of online retail and omnichannel fulfillment.